-

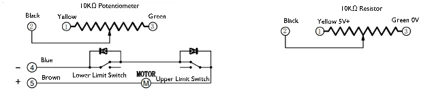

Unlimited switch, clutch mechanical limit protection

-

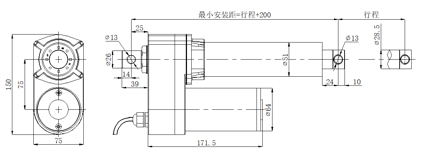

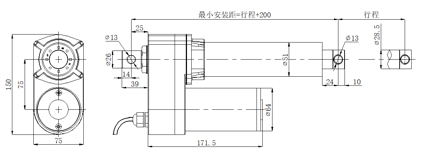

50 ≤ travel<599, minimum installation distance=travel+200

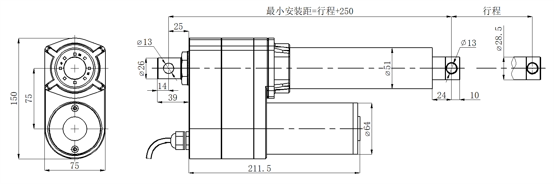

600 ≤ travel<1000, minimum installation distance=travel+250

1000 ≤ travel<1500, minimum installation distance=travel+300

-

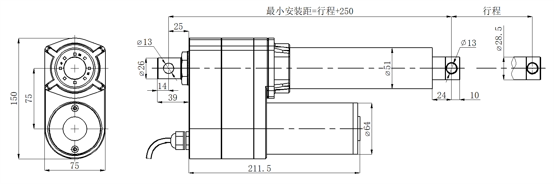

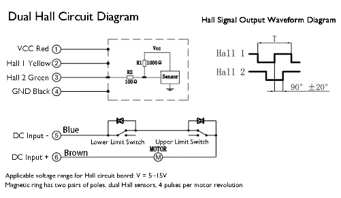

Built-in limit switch, clutch mechanical limit protection (optional potentiometer signal output)

-

50 ≤ travel<599, minimum installation distance=travel+250

600 ≤ travel<1000, minimum installation distance=travel+300

1000 ≤ travel<1500, minimum installation distance=travel+350

Advantages

High protection (IP65/IP66)

High structural strength (steel telescopic rod, copper nut)

Metal gears (long lifespan, impact resistance)

Strong self-locking force (built-in self-locking torsion spring), overcurrent protection

Disadvantages

High noise level (70db), generally recommended for outdoor use

Common Applications

Agricultural machinery, truck bucket lifting, and other applications with high load requirements and harsh operating environments

Low requirements for noise, stability, and protection level

Scenarios with demand

The front-end and back-end connectors can be customized

|

Code

|

Gear Ratio

|

Screw Lead

|

No-load speed(mm/s)

|

Full load speed(mm/s)

|

Ex-factory standard(N)

|

Self-locking force(N)

|

No-load Current(A)

|

Load Current(A)

|

Maximum travel of built-in switch(mm)

|

|

12V

|

24V

|

36V

|

48V

|

12V

|

24V

|

36V

|

48V

|

|

A1

|

41

|

3

|

5.0

|

3.5

|

10000

|

11000

|

3

|

1.5

|

1.3

|

1.1

|

20

|

12

|

9

|

6

|

620

|

|

B1

|

30

|

6.6

|

4.8

|

9000

|

10000

|

|

C1

|

20

|

10.0

|

7.1

|

6000

|

7000

|

|

D1

|

10

|

20.0

|

14.5

|

3000

|

3500

|

|

E1

|

5

|

40.0

|

29.0

|

1500

|

1500

|

|

|

A2

|

41

|

4

|

6.5

|

4.7

|

9000

|

9500

|

3

|

1.5

|

1.3

|

1.1

|

20

|

12

|

9

|

6

|

827

|

|

B2

|

30

|

9.0

|

6.4

|

7500

|

8000

|

|

C2

|

20

|

13.0

|

9.5

|

5000

|

5500

|

|

D2

|

10

|

26.0

|

19.3

|

2000

|

2500

|

|

E2

|

5

|

50.0

|

38.7

|

1000

|

1500

|

|

|

A3

|

41

|

5

|

8.0

|

5.9

|

7000

|

8000

|

3

|

1.5

|

1.3

|

1.1

|

20

|

12

|

9

|

6

|

1033

|

|

B3

|

30

|

11.0

|

8.0

|

6000

|

6500

|

|

C3

|

20

|

16.0

|

11.8

|

4000

|

4500

|

|

D3

|

10

|

33.0

|

24.2

|

1500

|

2000

|

|

E3

|

5

|

65.0

|

48.3

|

800

|

1500

|

|

|

A4

|

41

|

7.5

|

12.0

|

8.8

|

5000

|

5500

|

3

|

1.5

|

1.3

|

1.1

|

20

|

12

|

9

|

6

|

1550

|

|

B4

|

30

|

16.0

|

12.0

|

4000

|

4500

|

|

C4

|

20

|

24.0

|

17.7

|

2500

|

3000

|

|

D4

|

10

|

50.0

|

36.3

|

1000

|

1500

|

|

E4

|

5

|

100.0

|

72.5

|

500

|

800

|

|

|

A5

|

41

|

12

|

19.0

|

14.1

|

3000

|

3500

|

3

|

1.5

|

1.3

|

1.1

|

20

|

12

|

9

|

6

|

2480

|

|

B5

|

30

|

26.0

|

19.2

|

2500

|

3000

|

|

C5

|

20

|

39.0

|

28.4

|

1500

|

2000

|

|

D5

|

10

|

80.0

|

58.0

|

500

|

800

|

|

E5

|

5

|

160.0

|

116.0

|

300

|

500

|

Note: The measured data in the table is at room temperature. Due to the processing and installation accuracy of parts, there may be errors, with the maximum deviation of ± 10%

Mechanical Configuration

Front/Rear Joint Styles: Available in standard options or customizable

Ball screw, copper nut, timing belt drive, manual crank function, or full IP66 protection can be selected per customer requirements.

Standard brushed motors available. Optional stepper, servo, or brushless motors (motor dimensions must not exceed 60×60mm; no height restriction). Electromagnetic brakes can be freely combined to achieve emergency stopping of the actuator.